$1800.00 Original price was: $1800.00.$1500.00Current price is: $1500.00.

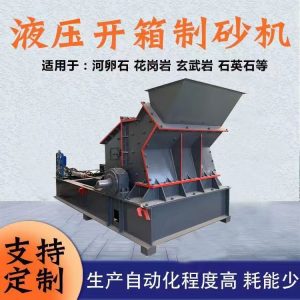

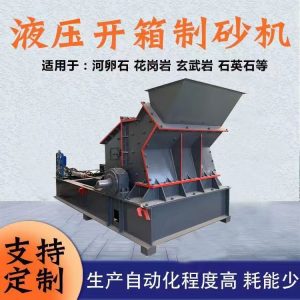

Hydraulic unpacking sand making machine is an advanced sand making equipment. The following will introduce its working principle, structural characteristics, performance advantages, application fields and other dimensions in detail:

Working principle

Impact crushing principle: Driven by the motor, the rotor rotates at high speed. After the material enters the crushing chamber, it impacts and crushes with the plate hammer on the rotor, and then enters the second fine crushing chamber for further crushing, and finally discharged from the discharge port. In this process, not only the impact crushing between the material and the plate hammer and the liner is formed, but also the stone-to-stone shaping 811 between each plate hammer and in the crushing chamber is completed.

Stone-to-stone and stone-to-iron method: The hydraulic unpacking sand making machine can choose two methods of stone-to-stone and stone-to-iron in terms of crushing principle. In the stone-to-stone method, the materials impact and collide with each other in the crushing chamber to achieve self-crushing. It is suitable for materials with higher hardness and can effectively reduce equipment wear; the stone-to-iron method is that the material is mainly impacted and crushed with metal parts such as plate hammers. It is suitable for softer materials and can improve the crushing efficiency 5.

Structural features

Hydraulic opening system: equipped with advanced hydraulic opening device, the outer shell of the sand making machine can be opened with one button, and the hammer and other accessories can be replaced conveniently and quickly, which greatly shortens the maintenance time of the equipment and improves production efficiency1.

Optimized crushing chamber: adopts a unique geometric shape design to improve the movement state of the material in the chamber, achieve a higher crushing ratio and better particle size distribution, and can effectively reduce energy consumption.

Wear-resistant tool: The tool is generally made of wear-resistant alloy material and undergoes a precise heat treatment process. It has stronger wear resistance, extends service life, and reduces maintenance frequency.

Keyless connection: The equipment adopts a keyless connection method, which makes the overall strength high, easy to use, and low maintenance rate3.

Performance advantages

High production efficiency: It can achieve continuous operation, large processing capacity, high line speed and fast operation during operation. Compared with traditional sand making equipment, the production efficiency is significantly improved8.

Good sand making effect: The finished stone is cubic, without tension and cracks, and has a good grain shape. The sand and gravel produced are uniform in particle size, good in particle shape, and high in compressive strength. They are more in line with the requirements of high-standard construction sand than natural sand and hammer crusher sand and gravel13.

Energy saving and consumption reduction: It has the characteristics of low energy consumption. Compared with traditional sand making equipment, it can significantly reduce energy consumption in the production process. The size of the inlet and outlet is adjustable, and the material can be crushed to different degrees to reduce energy consumption. After the small pieces of material are processed by the sand making machine, they can become qualified sand and gravel, without secondary treatment, saving costs911.

Excellent environmental protection performance: There is a vortex chamber inside the equipment, and the air is cleverly self-circulated, which further eliminates dust pollution. At the same time, the sealing performance is good, the structure is compact, and dust is effectively prevented from entering, reducing noise, and realizing green production9.

Long service life: The hammer head, liner and other wearing parts are made of wear-resistant materials, with high wear resistance and long service life. The overall structure of the equipment is firm and stable, the failure rate is low, and the maintenance workload is small, which reduces the need for frequent replacement and maintenance, thereby reducing maintenance costs and resource consumption911.

Application field 1

Construction industry: used to produce construction sand, provide high-quality sand and gravel aggregates for high-rise buildings, municipal engineering, concrete mixing plants, etc., which can effectively improve the strength and durability of concrete.

Road and bridge construction: various rocks can be crushed into suitable particle sizes for the pavement base and subbase laying in infrastructure construction such as highways, high-speed railways, bridges, etc.

Mining industry: suitable for fine crushing of various ores, such as granite, basalt, limestone, river pebbles, iron ore, bauxite, etc., to help mining companies improve the utilization rate and economic benefits of ores.

Construction waste treatment: construction waste such as waste floor slabs, bricks, tiles, concrete, etc. can be crushed into recycled aggregates to achieve resource reuse, reduce the pollution of construction waste to the environment, and also reduce construction costs9.

Precautions

Site selection: a well-ventilated and flat site should be selected to avoid damage to the equipment by high temperature, humidity and corrosive gases.

Material humidity control: Excessive material humidity may affect the crushing efficiency of the equipment and even cause damage to the equipment itself. The humidity of the material should be controlled as much as possible. The moisture content in the material can be reduced by natural drying or mechanical dehydration. 10.

Equipment maintenance: Strictly follow the operating procedures, regularly inspect, maintain and service the equipment, and eliminate faults in time to ensure the normal operation and high-yield operation of the equipment.

Only logged in customers who have purchased this product may leave a review.

Add us for more information.

Reviews

There are no reviews yet.