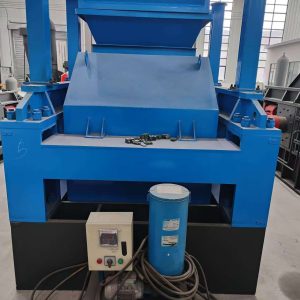

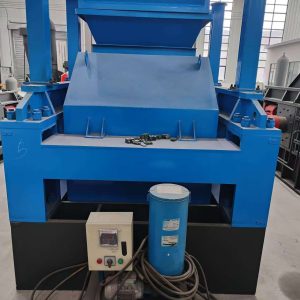

$5800.00 Original price was: $5800.00.$4950.00Current price is: $4950.00.

Roller sand making machine, also known as double roller sand making machine, is widely used in sand making, mineral processing, cement, metallurgy, chemical industry, building materials and other industrial sectors2. The following is a detailed introduction about it:

Working principle

When the material enters the crushing chamber of the machine, it is forced to pass between the two rollers by the meshing force of the rotating roller shaft, and at the same time begins to break due to the squeezing and shearing of the roller shaft. The broken small particles are thrown to the bottom of the machine along the tangent of the roller rotation through the gap between the two roller shafts. The large particles exceeding the gap continue to be broken into small particles and discharged2.

Structural composition2

Roller: It is the core component of the equipment. The surfaces of the two rollers can be designed with teeth or smooth, and the crushing is achieved by squeezing the materials against each other.

Feed port: The material enters between the two rollers from here.

Discharge port: The crushed material is discharged from here.

<img src=”data:;base64,” alt=”” aria-hidden=”true” />

Mechanical equipment Roller sand making machine discharge port

Adjustment device: used to adjust the gap between the two rollers to control the particle size of the finished product. Common wedge-shaped or gasket adjustment devices are available.

Motor: Provides power source for the equipment. Traditional models may be directly driven by belts, while hydraulic roller sand making machines are driven by hydraulic systems to provide stronger power and stability.

Lubrication system: such as oil pump lubrication, to ensure good lubrication of the two-way tooth rollers and reduce wear.

Frame structure: Supports the entire machine body to ensure stable operation of the equipment.

Advantages

Large crushing ratio: It can crush materials into sand and gravel of various specifications to meet different needs. The crushing ratio is usually in the range of 3-84.

The finished product has uniform particle size: The discharging particle size is controllable and the particle shape is good. By adjusting the distance between the two crushing rollers, the discharging particle size can be easily controlled. It can stably output high-quality sand and gravel that meet the standards, and there is basically no needle-like shape4.

Energy saving and consumption reduction: The structure is compact and the power consumption is relatively low. The extrusion crushing method is adopted. Compared with the traditional impact crushing, it can effectively reduce energy consumption and help reduce production costs.

Easy operation and convenient maintenance: The design is simple, easy for daily operation and maintenance, the replacement cycle of wearing parts is long, and the maintenance personnel can quickly locate the problem, efficiently complete the replacement and maintenance work, and reduce downtime4.

Safety and environmental protection: low operating noise, reducing environmental pollution. Some new double-roller sand making machines are also equipped with a scraper system to solve the problem of bonding of materials with high water content and further reduce dust pollution.

Wide range of applications: suitable for a variety of materials, such as limestone, dolomite, granite, river pebbles, cobblestones, iron ore, quartz stone, etc., and have strong adaptability to materials, with a daily output ranging from tens of tons to thousands of tons1.

Disadvantages

Large equipment volume: requires a large production space and is not suitable for mobile production.

High requirements for material humidity: when the humidity is high, it may affect the crushing effect and even cause equipment blockage.

High energy consumption: compared with some other types of sand making machines, the double-roller sand making machine consumes relatively high energy during the crushing process.

Application areas

Construction industry: Provide high-quality sand and gravel for high-rise buildings, residential areas, etc. for concrete preparation, which can significantly improve the working performance of concrete and enhance the stability of building structures4.

Road construction: Provide suitable sand and gravel for road base and pavement paving to ensure the strength and durability of highways4.

Water conservancy projects: Assist in the concrete pouring of dams, riverbanks and other facilities, and ensure the waterproof and anti-seepage performance of the project with high-quality sand and gravel4.

Mineral processing industry: It can effectively process ores of various hardness, including metal ores such as gold, copper, and iron, as well as non-metallic ores. The crushing process is gentle, which can effectively reduce the over-crushing of ores, maintain the integrity of mineral crystals, and facilitate subsequent mineral sorting.

Only logged in customers who have purchased this product may leave a review.

Add us for more information.

Reviews

There are no reviews yet.