$48000.00 Original price was: $48000.00.$39000.00Current price is: $39000.00.

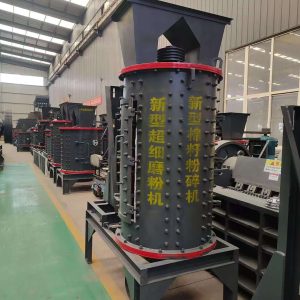

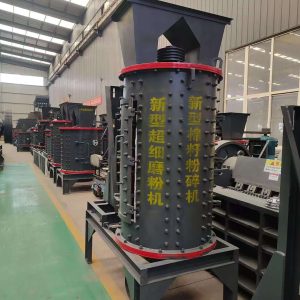

Related introduction of sand making machine:

Working principle

Sand making machine mainly relies on the impact of working parts on materials and materials on materials to achieve crushing. The material enters from the top and falls to the center of the high-speed rotating rotor. Under the centrifugal force of the rotor, it is thrown out at high speed and hits the impact plate inside the main machine to achieve crushing.

Common types

Horizontal hammer sand making machine: mainly PX high-efficiency fine crusher, including split hammer head structure and integral hammer head structure. The split hammer head adopts high-strength wear-resistant material and has a long life; the integral structure is relatively simple, but the hammer head is easy to wear.

Vertical shaft hammer sand making machine: mainly used for second-level or third-level fine crushing, can handle a variety of coarse, medium and fine materials, and is widely used in hydropower, highways, artificial sand and gravel and other industries.

Third-generation sand making machine: also called high-efficiency fine crusher, impact sand making machine. Driven by the motor, the rotor rotates at high speed, the material enters the crushing chamber and impacts with the plate hammer to crush, and then enters the second crushing chamber to crush, while completing the stone-to-stone shaping, and finally discharged from the discharge port.

The sixth generation of sand making machine: Based on the third generation, a counterweight wheel is added to save electricity, increase kinetic energy, and improve production efficiency; an impact plate adjustment device is added to make it easier and quicker to adjust the fineness of the discharge; a maintenance observation door is opened on the side, which is more conducive to maintenance and observation.

Vertical shaft impact sand making machine: According to the rotor structure, it is divided into an open rotor structure and a closed rotor structure. The closed rotor structure is a cage-shaped layout of the rotor, and the material falls into the closed rotor from the top.

Roller sand making machine: It has some applications in the field of small-capacity sand making. It is the first new type of sand making machine to use hydraulic start. It has good energy-saving effect, but its long-term reliability is poor and the equipment failure rate is high.

VSI sand making machine: It is developed and produced with the introduction of advanced German technology. It has two types: “stone hitting stone” and “stone hitting iron”. The “stone hitting stone” type is used for processing materials with strong abrasiveness, and the “stone hitting iron” type is used for processing materials with low abrasiveness.

Performance characteristics

Simple structure and convenient maintenance: The structure of sand making machine equipment is usually simple and there are no complex parts, so daily maintenance and maintenance work is relatively easy, reducing maintenance costs and downtime.

Efficient energy saving, high crushing efficiency: Under the same power, the new sand making machine has a 30% higher output than traditional equipment and is stable. At the same time, the consumption of wearing parts is low, and the operating cost is 30% lower than that of traditional equipment.

Excellent product particle shape: The product is cubic, with good particle shape, reasonable grading, and adjustable fineness modulus. It is particularly suitable for artificial sand making and stone shaping. Practice has proved that the sand making and shaping effect of other traditional equipment is 30% higher.

Wide range of application: It can be used for artificial sand making of river pebbles, mountain stones, ore tailings, and stone chips. It can also be used in the production of building aggregates, road surface materials, cushion materials, etc. It is also widely used in engineering fields such as water conservancy and hydropower, high-grade highways, high-speed railways, and the front-end fine crushing process of grinding in the mining field.

Only logged in customers who have purchased this product may leave a review.

Add us for more information.

Reviews

There are no reviews yet.